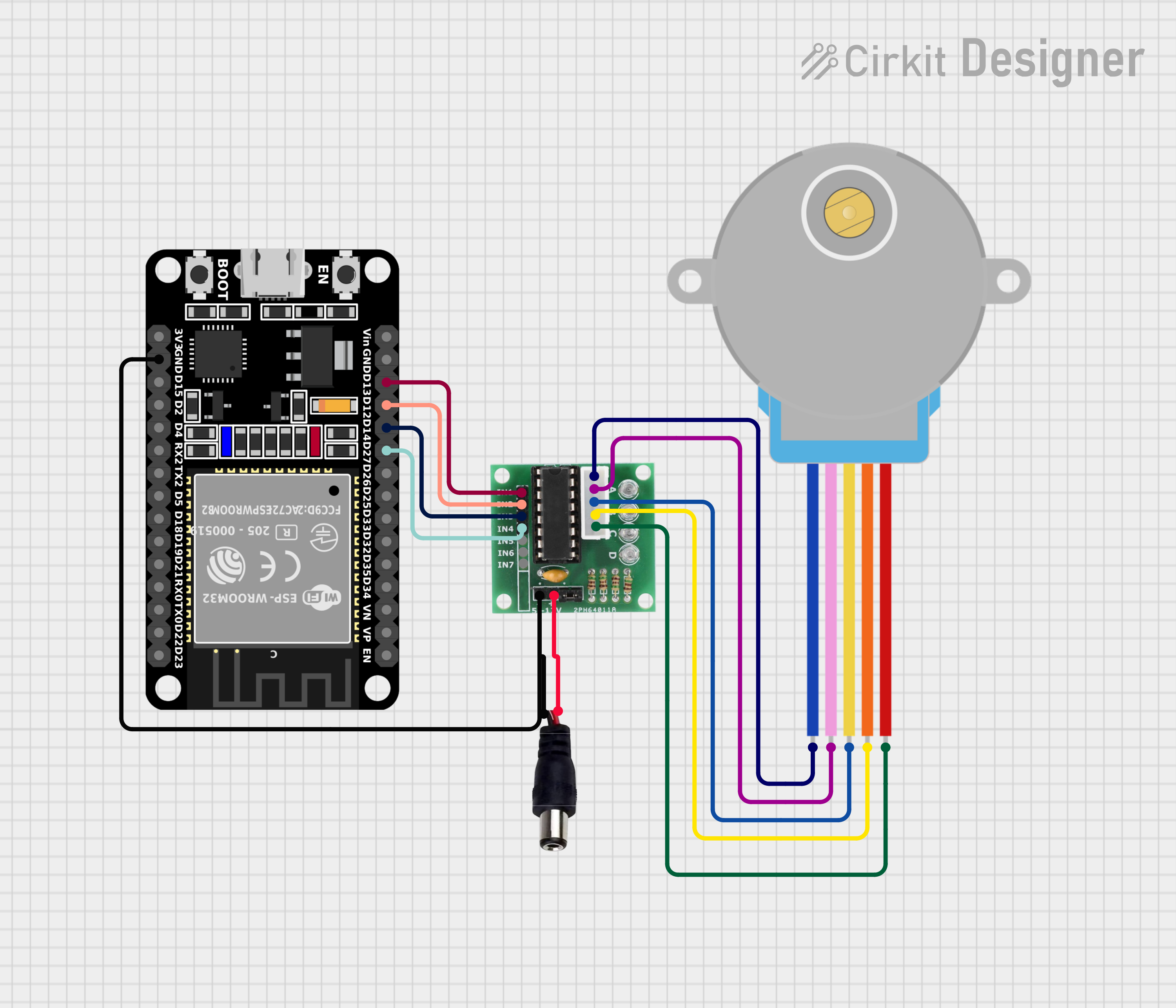

ESP32, ULN2003, and 28BYJ-48: A DIY Stepper Motor Control Project

Introduction In the realm of DIY electronics, stepper motors are versatile components that can be used to create a wide range of projects, from 3D printers to robotic arms. The ESP32, a powerful microcontroller, coupled with a ULN2003 driver and a 28BYJ-48 stepper motor, provides a robust and affordable solution for precise motor control. In this blog post, we’ll delve into the specifics of this combination and guide you through a basic setup.

Understanding the Components

- ESP32:

- A versatile microcontroller with Wi-Fi and Bluetooth capabilities.

- Offers a wide range of GPIO pins for controlling various devices.

- Supports multiple programming languages, including Arduino and MicroPython.

- ULN2003:

- A Darlington transistor array that acts as a driver for stepper motors.

- Amplifies the low-current signals from the microcontroller to drive the higher-current requirements of the motor.

- Protects the microcontroller from potential damage caused by the motor’s back EMF.

- 28BYJ-48:

- A unipolar stepper motor with a 48-step resolution per revolution.

- Commonly used in DIY projects due to its low cost and ease of use.

- Requires a driver to control its four coils.

C++

#include<Stepper.h>

const int stepsPerRevolution = 2048; // Calculated based on 48 steps/rev and 42 microstepping

const int motorPin1 = 12;

const int motorPin2 = 13;

const int motorPin3 = 14;

const int motorPin4 = 27;

Stepper myStepper(stepsPerRevolution, motorPin1, motorPin2, motorPin3, motorPin4);

void setup() {

myStepper.setSpeed(60); // Adjust speed as needed

}

void loop() {

myStepper.step(stepsPerRevolution / 2); // Half rotation

delay(1000);

myStepper.step(-stepsPerRevolution / 2); // Half rotation backward

delay(1000);

}

Explanation:

- Include the Stepper Library: Incorporate the

Stepperlibrary to simplify motor control. - Define Constants: Set the steps per revolution, which is calculated based on the motor’s step resolution and the desired microstepping.

- Create a Stepper Object: Instantiate a

Stepperobject, specifying the number of steps per revolution and the pins connected to the motor. - Set the Speed: Use the

setSpeed()function to adjust the motor’s rotation speed. - Control the Motor: Employ the

step()function to rotate the motor in either direction. Positive values rotate clockwise, and negative values rotate counterclockwise.

Expanding Your Project

Once you have a basic understanding of the setup, you can explore more advanced applications:

- Microstepping: Increase the motor’s resolution by dividing each full step into smaller increments.

- Closed-Loop Control: Use sensors like encoders or potentiometers to precisely control the motor’s position.

- Complex Motion Profiles: Implement smooth acceleration, deceleration, and velocity profiles for precise movement.

- Wireless Control: Utilize the ESP32’s Wi-Fi or Bluetooth capabilities to control the motor remotely.

By combining the power of the ESP32, the driving capabilities of the ULN2003, and the precision of the 28BYJ-48 stepper motor, you can create a wide range of innovative projects.

Leave a Reply

You must be logged in to post a comment.