Smart Control: Stepper Motor with ESP32

🔍 What is the 28BYJ-48 Stepper Motor?

The 28BYJ-48 is a 5V unipolar stepper motor with a built-in reduction gearbox. This makes it ideal for applications requiring precise control at low speed.

🧾 Specifications

| Specification | Value |

|---|---|

| Motor Type | Unipolar Stepper |

| Rated Voltage | 5V DC |

| Number of Phases | 4 |

| Coil Resistance | ~50Ω per coil |

| Step Angle (before gearbox) | 11.25° |

| Gear Reduction Ratio | ~64:1 (actually ~63.68395:1) |

| Steps Per Revolution (output shaft) | 2048 steps |

| Holding Torque | ~300 gf·cm |

| Wires | 5 |

| Max Current | ~240mA (safe at ~100–200mA) |

🔁 How Does It Work?

- The motor has 4 coils and a common wire (VCC).

- Coils are energized in a sequence to rotate the internal rotor.

- The gearbox slows down output but increases torque and precision.

⚙️ Full Output Shaft Rotation:

- Internal motor steps: 32 steps/rev (11.25° each)

- Gearbox: 63.68395:1 ratio

- Result:

32 × 63.68395 ≈ 2048 steps/rev

That’s 0.176° per step – very precise!

🎯 Advantages of 28BYJ-48

✅ Low voltage (5V) – safe for microcontrollers

✅ High torque due to gearbox

✅ Fine step resolution (2048 steps/rev)

✅ Cheap and widely available

✅ Compatible with ULN2003 board

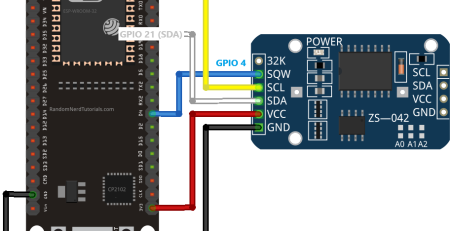

🧲 Wiring Details

5 Wires (typically colored):

| Color | Function | ULN2003 IN Pin |

|---|---|---|

| Red | VCC (common) | Motor power (not IN) |

| Blue | Coil 1 (A) | IN1 |

| Pink | Coil 2 (B) | IN2 |

| Yellow | Coil 3 (C) | IN3 |

| Orange | Coil 4 (D) | IN4 |

🧪 Test & Troubleshooting

- Motor not rotating? Check wiring and ULN2003 power.

- Wrong direction? Reverse coil order (e.g., IN1 ↔ IN4).

- Skipping steps? Add delay or check power supply.

- Weak torque? Use a stronger 5V supply (≥500mA).

🛠 Advanced Tips

- Use AccelStepper library for smoother motion.

- Gearbox introduces backlash – not ideal for fast direction changes.

- Not suitable for high-speed applications.

- Use microcontroller sleep or disable pins to reduce heat when idle.

🔧 Real-Life Applications

- Robot arms and legs (slow, accurate movement)

- Camera sliders

- Smart blinds/curtains

- Automatic locks

- Hobby CNC or XY plotters (light-duty)

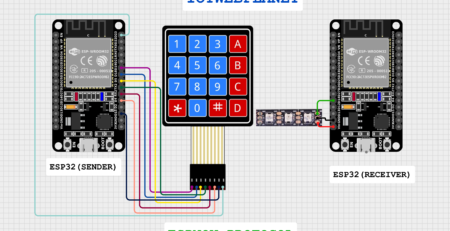

HOW TO OPERATE

#include <Stepper.h>

const int stepsPerRevolution = 2048; // or the actual steps per revolution

#define IN1 19

#define IN2 18

#define IN3 5

#define IN4 17

Stepper myStepper(stepsPerRevolution, IN1, IN3, IN2, IN4);

void setup() {

Serial.begin(115200);

myStepper.setSpeed(15); // Set speed in RPM

}

void loop() {

Serial.println("Clockwise");

myStepper.step(stepsPerRevolution);

delay(1000);

Serial.println("Counterclockwise");

myStepper.step(-stepsPerRevolution);

delay(1000);

}

Leave a Reply

You must be logged in to post a comment.